The Hilti MT System for the lift sector

Hilti specifically expanded its new MT assembly system with wall connections for beam profiles, connections for pillars and attachment elements for rail consoles to allow it to be used by the lift sector for support structures.

The individual components were specially analysed and tested based on the requirements of the lift sector to ensure the Hilti design software supported lift-specific requirements. A modular solution for the complete safety-relevant separation of the shafts from each other will be integrated in the near future. As a result, the lift sector will make enormous progress towards modular systems for shaft support structures.

Development initially concentrated on the simple partition supports between the front and back shaft wall. Special wall connections were developed that keep the beam in position without attachment and support the capacity of beams cut to a uniform length to compensate a shaft tolerance of up to +/-40 mm.

In addition, special rail connections were developed that allow the lift manufacturers’ standard attachment consoles for rails to be supported completely on the 50- or 100-mm beam profile. This makes fine adjustment of the position of the guidance rails possible despite the mounting holes occurring at equal distances.

Assembly system expanded

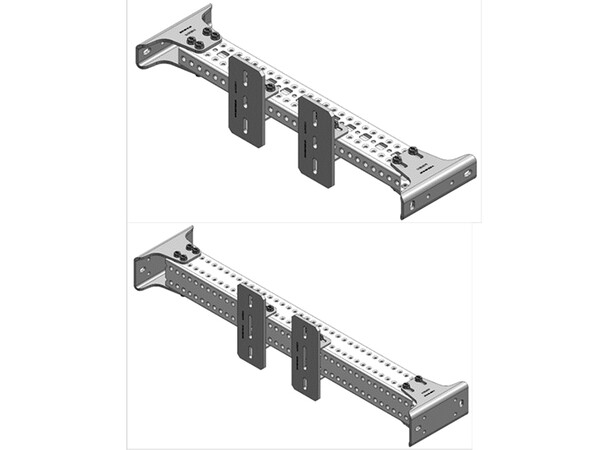

Versions of the Hilti MT partition support. Photo: © Hilti

Versions of the Hilti MT partition support. Photo: © HiltiSubsequently, consideration was given to cases where the front wall of the shaft is completely missing or the side walls consist of material of deficient load-bearing capacity, making secure anchoring of the rails and partition supports only possible in the concrete of the ceiling. The beam profiles of the MT assembly systems can run through the shaft vertically as pillars and be attached to the ceiling.

Hilti has expanded its assembly system with connections that support the attachment of the vertical partition beam to horizontal pillars. Consequently, a partition support can be provided at intervals of 2.5 cm, irrespective of whether anchoring of the rail consoles in concrete is possible at this position.

Load tests for every system component

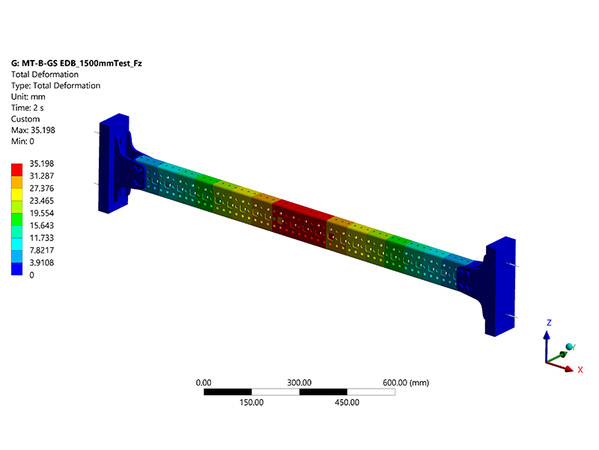

The technical configuration of the partition support is supported by proprietary design software, which is based on the powerful RSTAB structural analysis program. Finite element (FE) models of the individual components and overall system were developed with the ANSYS 2020 software to determine the behaviour of the system under load. TÜV Süd certified the design software.

The FE models were verified by means of practical load tests for every system component. The figure shows the comparison of the technical data from the numerical simulation with the results from practical tests for a complete two metre long partition support. The stress curves in the individual components and in the complete system were determined and documented in detail.

The following configuration was used for the case in the figure: the S350 model was taken as a basis for the beam profile and the S355 model for the wall connection with a total of 93,000 elements and 608,000 nodes. The results of the practical tests and numerical simulation are filed in the database of the design software as a basis for the technical design.

Comprehensive report

Photo: © Hilti

Photo: © HiltiThe Hilti design software “Profis Installation” creates a comprehensive report of the design of the structure. The input data with regard to the forces acting on the guide rails as well as the geometric positioning of the guide rails using rail brackets on the partition supports are documented. This is supported by a schematic diagram of the partition support.

As a result of the configuration, a particular support profile and matching connection elements are proposed and their capacity utilisation documented in relation to the forces in the components. In addition, the deflection of the partition supports is displayed at the point where the guide rails are attached.´

An interface for the Hilti dowel calculation software PROFIS Engineering supports the simultaneous configuration of the anchoring of the partition support on the shaft walls and documents the various proposed anchor systems with their capacity utilisation.

Centrally controlled quality assurance

The well-documented design of the modular structure composed of simple standard components and the worldwide availability in equivalent high quality via the Hilti direct sales network support global lift manufacturers in integrating support structures as standard in their lift design for their different lift types.

As a result, centrally controlled quality assurance of the support structures in combination with the lift type is promoted and the effort of the Group branches is enormously reduced for procuring structures while installation is simplified and process reliability enhanced.

In many countries, where the general contractor is responsible for the creation of the support structures as part of the lift shaft, lift companies can take on this partial package on their own responsibility and in this way boost turnover and the prospect of profitability.

More information: hilti.com

Why does the lift sector use assembly systems so seldom?

Write a comment