New generation of car buffers

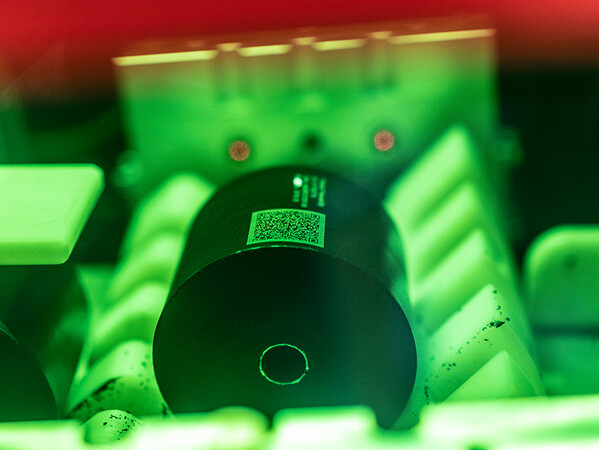

The D-series lift buffers made by P+S Polyurethan-Elastomere have been supplemented by a new generation of components with improved performance.

As a result, four new buffer types will in future be able to represent almost the entire load spectrum of the D-series currently available on the market. "At the same time, we can normally always use a smaller component," according to Daniel Semprecht, sales director of P+S.

The advantages:

- 1:1 exchangeability with D-series and alternative products

- compact design (counterweight frame)

- reduced number of versions

- more uniform systems

- simplified logistics / storage

Contribution to sustainability

Photo: © P+S Polyurethan-Elastomere

Photo: © P+S Polyurethan-ElastomereDuring the development of the new series, the focus were the sizes and load ranges currently available on the market. Many manufacturers currently obtain system-relevant articles from several procurement sources and therefore standardise the load ranges.

"Looking further afield and integrating knowledge about market needs in the components was important to us," Semprecht emphasised.

In future, replacing a current car buffer D" (Ø 100xHeight80mm) with a D0-55 (Ø 80xHeight80mm) will be possible. This will permit transporting a larger number of components in each shipment. In this way, the company based in Diepholz (Germany), certified according to 9001:2015, 14001:2015 and 45001:2018, is also making a contribution to sustainability.

Sturdy and durable

Photo: © P+S Polyurethan-Elastomere

Photo: © P+S Polyurethan-ElastomereThe new generation of components is based on the material Diepocell BM. According to P+S Polyurethan-Elastomere, this material is especially sturdy and durable, even when deployed in areas with high humidity.

The new generation of components has already been successfully certified according to EN81-20/50:2020 and BS EN 81-20/50:2014. Additional approvals for worldwide use are being prepared.

The new buffer series was developed on the company’s own test stand on which free fall experiments / dynamic testing up to 5m/s can also be carried out for other applications and designs. "The close cooperation of the development department of P+S with the certifying test bodies produced a buffer series that also permits use in compact installation situations and simultaneously features tremendous technical properties," the company emphasised.

More information: pus-polyurethan.de

Write a comment