Structure-borne noise emissions on the lift according to DIN 8989

How is structure-borne noise measured in synchronous and asynchronous drives without machine room?

An important factor in the quality assessment of a lift is the transfer of structure-borne noise to the lift shaft wall ( ). When using synchronous and asynchronous drives in lift systems without a machine room, it is not airborne sound but structure-borne sound that plays the decisive role in the emissions.

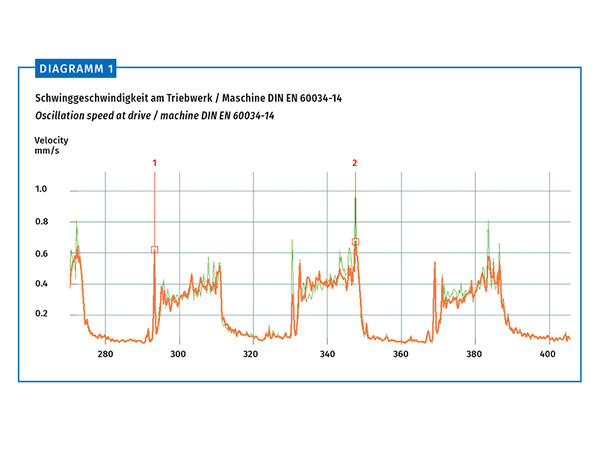

Oscillation speed at drive/machine DIN EN 60034-14. Photo: © Ulrich Nees / Jan König

Oscillation speed at drive/machine DIN EN 60034-14. Photo: © Ulrich Nees / Jan KönigDue to the low speeds in the range of approx. 100 min-1 to 300 min-1 of the synchronous and asynchronous drives without transmission, low frequency oscillations and noises are emitted via the lift shaft wall to neighbouring rooms or those deserving protection.

Noises are low frequency in a frequency range below 90 Hz. In order to be able to decide whether a noise is low frequency, both A-weighted noise levels as well C-weighted noise levels are measured as far as possible simultaneously and the corresponding permanent noise level in the measuring period determined in each case.

Structure-borne noise is transmitted to the shaft wall

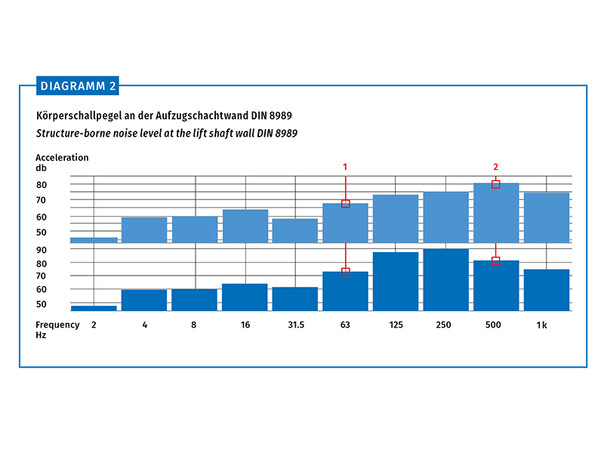

Structure-borne noise level at the lift shaft wall DIN 8989. Photo: © Ulrich Nees / Jan König

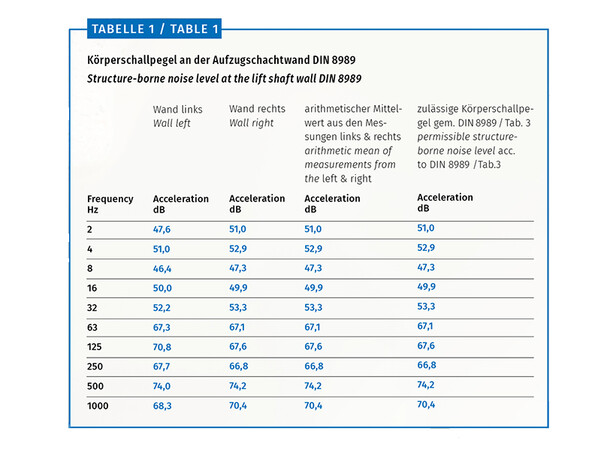

Structure-borne noise level at the lift shaft wall DIN 8989. Photo: © Ulrich Nees / Jan KönigThe DIN 8989 / Table 3 "Noise emission values of lifts to achieve noise protection targets" contains information about the maximum permissible air- and structure-borne noise emissions by lifts. They are oriented to the position of the lift shaft in relation to the rooms deserving protection, taking the room volume into account.

Diagram 1 shows the oscillation speed measured at the drive, Diagram 2 and Table 1 show the resulting structure-borne noise level [dB] emitted via the drive frame to the shaft wall.

Summary: Structure-borne noise is transmitted by the lift or lift components used (including motor mount and rail brackets) to the shaft wall.

Structure-borne noise level at the lift shaft wall DIN 8989. Photo: © Ulrich Nees / Jan König

Structure-borne noise level at the lift shaft wall DIN 8989. Photo: © Ulrich Nees / Jan KönigThe following must be borne in mind:

– Oscillation speed of drive/machine

– Structure-borne noise transfer from the drive-/motor mount to the shaft wall

– Structure-borne noise transfer from the rail brackets to the shaft wall

This shows that the mounting of drives or motors is an important factor. This will be the subject in the next issue.

Jan König is the proprietor of the engineering firm (VID) Ing4Lifts.

Ulrich Nees is the proprietor of "Aufzug-Systeme + Beratung Ulrich Nees".

More information: ing4lifts.de

aufzugsystemeberatung.de

Write a comment