How much lift does a building need?

Long impatient waits for lifts? Many users have to experience this and they often vent their irritation about it to their specialist companies. But how much lift does a building absolutely need to reduce or optimise the waiting time to what feels normal?

By Alexander Rath

Rule of thumb for residential buildings

In residential buildings with up to twelve residential units and six floors, one lift with a 630 kg payload is normally enough for up to eight people. However, a payload of 1,000 kg and 13 people would be better in order to have the option of furniture or stretcher transport.

The design of the car depends on the requirements of the property and if applicable regional construction requirements. The handling capacity can be roughly estimated here; normally, no comprehensive handling capacity analysis is needed. Consideration should also be given to a potential later change in the use of the building, which can involve completely different requirements. In this case, sustainability means already thinking of the future.

Rule of thumb for office buildings

The following rule of thumb can be used for an initial rough estimate of the lifts needed for office buildings:

Per 200 people =1 lift

To calculate the operating speed needed, the following applies: Conveyance height in metres divided by 25 = operating speed in metres per second. It then has to be rounded to the technically available standard speeds.

But careful: these results are only rough guidelines and something to go by. They must always be submitted to technical review.

ISO 8100-32 standard

Photo: © Juice FLair/Shutterstock.com

Photo: © Juice FLair/Shutterstock.comApplication of the ISO 8100-32 standard is far more precise. It refers to handling capacity (HC5/ Ch.req). This indicates what percentage of the building users can be brought by lift from the ground floor to their floors within five minutes. This is a quality feature for buildings and is normally specified by the building owner. Ideally, the HC5 value should be between eleven and fourteen percent.

An example: if the HC5 value is twelve percent, twelve percent of users of the building can be transported from the lobby to their floors within five minutes. If one assumes a total occupancy of the building of 1,000 people, this would be 120 people. The average waiting period here – i.e. the time from calling the lift until arrival of the car ("taw.req") - should not take longer than 30 seconds. If this is the case, all other transport types of this building also work.

Competition between capacity and waiting time

Classically, the goals of greater handling capacity (number of people) and lower waiting times are in conflict with each other. Optimisation of the handling capacity is usually achieved at the expense of waiting times and vice versa. For good lift design with optimal car sizes, doors, speeds and the ideal number of lifts, these two goals have to be weighed up against each other as well as possible.

Every property differs as much as the behaviour of the lift users – consequently, the guidelines for waiting times and handling capacity also always have to be calculated in individual cases. For this reason, only non-binding rules of thumb can be stated here.

A single-use property involves other circumstances than a building with mixed use. For example, flexible working hours, the joint use of workplaces or floors with special usage (e.g. the canteen on the highest floor) also influence lift performance.

When is a traffic calculation needed?

For new buildings

A calculation is in general advisable – above all, for hospitals, hotels and properties with a mixture of residential and commercial use. A calculation is also recommended for buildings with a conveyance height above 22 floors if all lifts do not travel to each floor.

This applies all the more since the main task of good lift exploitation is optimisation of the space requirement combined with adequate handling capacity. After all, every square metre in the floor plan multiplied by the number of stops represents the biggest cost factor of lifts in new construction.

For existing buildings

A traffic (re-)calculation is always needed if

• there are problems with handling capacity,

• a change in use is planned

• or the average waiting times are unreasonable

Photo: © Hundt Consult / Alexander Rath

Photo: © Hundt Consult / Alexander RathSince the lift or number of lifts is/are already given, a modernisation must look for optimisations – provided they can be realised. The handling capacity can be increased here by technical measures.

The measures can differ greatly, depending on the lift:

• installation of an intelligent controller / group controller,

• change of the controller from two to one button (to reduce faulty trips),

• change of the door-type from side-opening to centrally opening,

• installation of faster doors (door drives),

• facilitation of "approach with open doors",

• optimisation of the travel curve.

Furthermore, the operating speed has only a relatively small influence on the handling capacity and as a result also on the average waiting times. Reducing the time lost at stops is far more important.

Alexander Rath is branch manager Austria at Hundt Consult.

What factors impair handling capacity in buildings? The environmental factors can be:

1. Strong peaks in passenger flow, which arise, for example, due to a train station directly in front of the building or rigid working hour models.

2. The occupancy of the floors, e.g., by tenants with a lot of public traffic (authorities, doctors) – by contrast with a legal firm with individual workplace offices.

3. High inter-floor traffic due to different main access stops such as underground parking levels, a canteen on the upper floor or due to tenants who have leased office space distributed across several floors.

4. Changing ways of coming to work, such as altered underground bicycle parking spaces

5. The architecture of the building, which influences the frequency of stair use

6. Absence factors such as holidays, field service, illness or "VIP trips"

Lift-related factors can be:

1. Too few lifts

2. Too small as well as too large lifts, the car floor plan

3. Slow door opening and door closing times

4. Door sizes that are too small and the associated long entry and exit times

5. Too low acceleration and deceleration of the car

6. No advance-operation doors

7. Preparatory brake bleeding before departure

8. Too low operating speed

9. Control systems without smart parking stops (ideally, lifts learn when they wait at which stops in order to be able to process use frequencies faster).

10. Poorly set parameterisation with high stop lost times

11. Faults of a lift within a lift group (since the other lifts are still in operation, the fault in the individual lift is only noticed very late).

12. Tests, maintenance, etc. within the core working hours

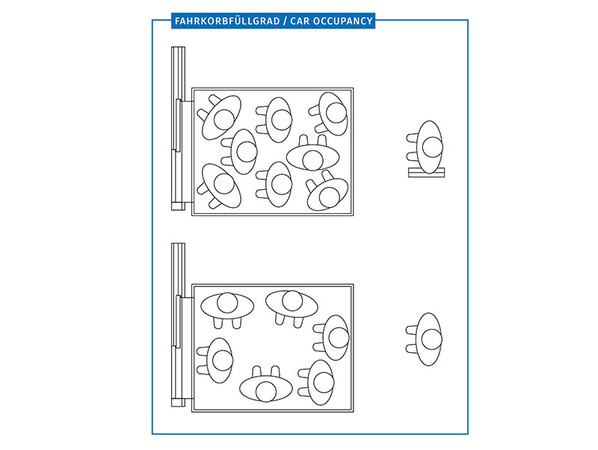

Box 2: Extended depth cars:

1. Limited suitability for office buildings

2. Telescopic doors are slow

3. 900 mm wide doors have a negative effect on entry and exit times

4. Car occupancy max. 70 percent – 1,000 kg = 13 passengers, i.e. maximum 9 passengers

5. Long entry and exit times due to car depth

Extended width car:

1. Suitable for office buildings

2. Centrally-opening doors are fast

3. 1,100 mm wide doors have a positive effect on entry and exit times

4. Car occupancy max. 70 percent – 1,000 kg = 13 passengers, i.e., maximum 9 passengers

5. short entry and exit times due to car design

Write a comment